Explore how to avoid costly mistakes during peak with proven strategies for smarter & faster shipping

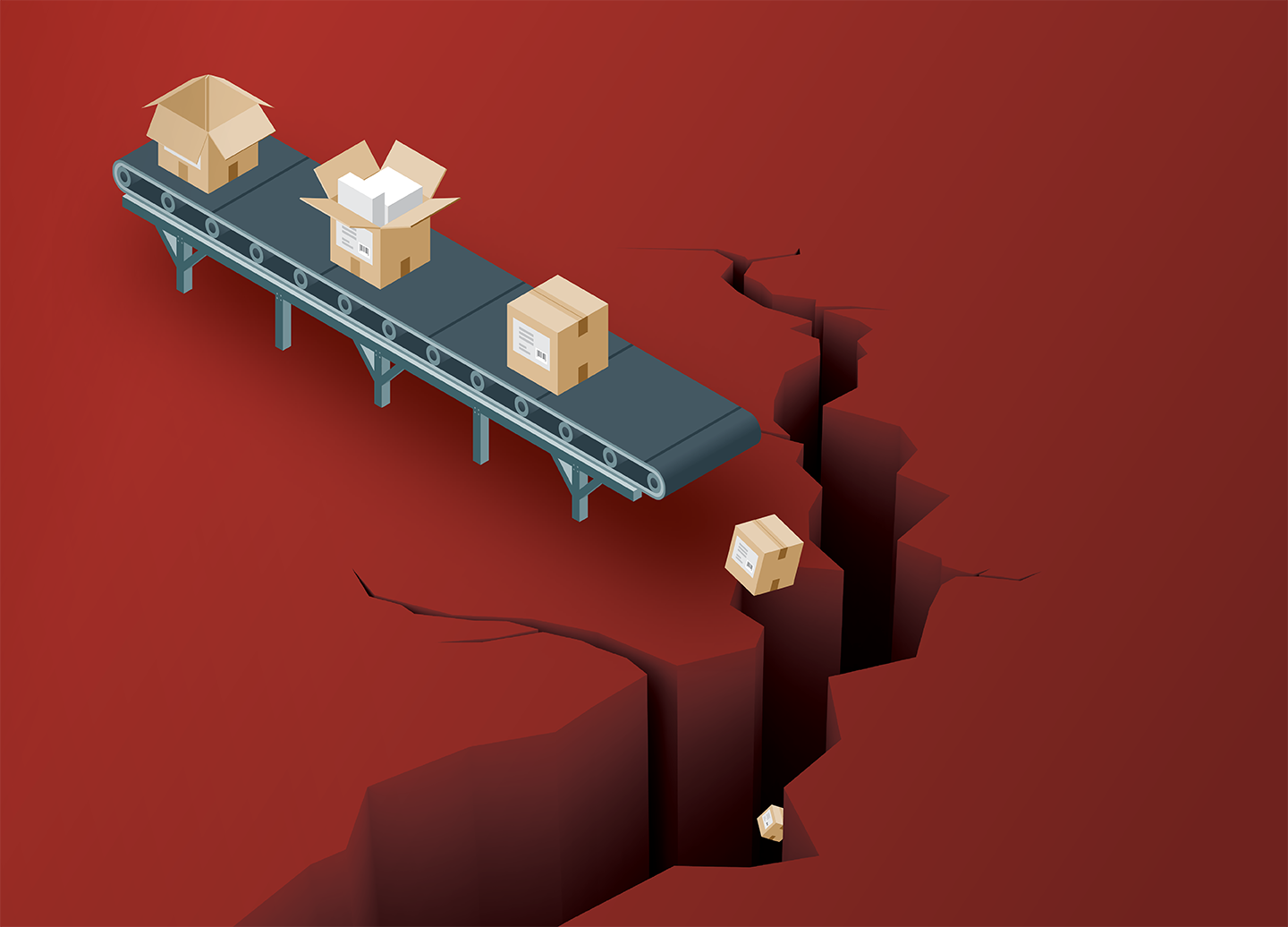

Peak season is here. Orders are flooding in, carriers are stretched to capacity, and your team is working at maximum speed. This is the most critical time of the year for shippers, and the margin for error is razor thin. While most advice focuses on what you should do, this guide takes a different approach: what you should avoid at all costs.

We are talking about major red flags. They can derail operations, damage customer trust, and cut into profits. Steering clear of these pitfalls will help you maintain control and deliver a peak season performance that customers remember for the right reasons.

Red Flags

🚩 1. Don’t Ignore Carrier Cutoff Times

Carrier cutoff times can shift daily during peak season and missing them can lead to delayed deliveries and unhappy customers. One missed cutoff can trigger a chain reaction of missed SLAs, refund requests, and negative reviews. Imagine promising two-day delivery, but your team ships after the cutoff. The package sits overnight and your guarantee becomes a broken promise. The fix? Automate cutoff alerts and integrate real-time carrier updates into your workflow using shipping software that can dynamically adjust based on carrier changes. Building this discipline into your daily operations is essential for maintaining reliability when every hour counts [Want to dive deeper into the current volatility? Why Parcel Shipping is Failing and What Comes Next].

🚩 2. Overpromising Delivery Dates

Aggressive delivery promises might win sales, but they can backfire when carriers are maxed out. Even expedited services can experience delays, and customers expect honesty during the holidays. A retailer that advertised “Guaranteed Christmas Delivery” without factoring in limited carrier capacity ended up issuing thousands of refunds and losing trust [Learn more about ways to manage capacity constraints]. Instead, set realistic expectations using real-time carrier performance data and communicate proactively. A simple message like “Due to high demand, delivery may take an extra day” on the website and at checkout can prevent angry calls and build credibility. The right shipping software stays focused on shipment execution while integrating with tech that can analyze carrier performance and pivots back to the shipping software to adjust delivery estimates on the fly.

🚩 3. Skipping Contingency Planning

Peak season is unpredictable. Weather delays, system outages, and carrier capacity issues can hit without warning. Businesses that relied on one carrier during the 2023 winter storm faced multi-day delays, while those with diversified strategies kept shipping. Contingency planning is essential, and leading shippers build redundancy into their strategy with alternative carriers and service levels ready to deploy [Discover how business rules enable you to pivot quicklyl when conditions change].

But contingency planning isn’t just about having backup carriers, it’s also about choosing the right carrier engine architecture. The way your shipping software connects to carriers (whether via API, on-platform, or a hybrid approach) can make or break your ability to respond quickly when disruptions hit. Want to understand how carrier engine decisions impact flexibility and resilience? Check out API, On-Platform, or Hybrid? The High-Stakes Carrier Engine Decision for Enterprise Parcel Shippers. Shipping software that supports multiple carriers and service levels makes switching seamless when things go wrong. Running “what-if” drills before peak season helps identify gaps before they become disasters, and ensures your team is ready for anything.

🚩 4. Sticking to Manual Processes

Manual rate shopping, label printing, or exception handling might work in slower months, but during peak season, they slow you down and increase errors. A warehouse team spending 10 seconds per label might not notice the drag in July, but in December, that delay compounds into hours of lost productivity. If label latency and transactional pricing are slowing your team, this analysis shows how those costs add up: When Parcel Shipping Software Starts Costing More Than It Saves. Automation is the answer. From rate shopping to compliance checks, shipping software can reduce errors and accelerate throughput. If you’re still relying on spreadsheets, now is the time to upgrade. Streamlining these processes not only saves time but also reduces operational friction, allowing your team to focus on what matters most. For a visual breakdown of how shipping software streamlines every step of the shipping journey, check out Cart-to-Delivery: How Shipping Software Streamlines Your Journey.

🚩 5. Forgetting About Returns

Outbound shipping gets all the attention during peak season but returns spike too. A poor returns experience can turn a holiday shopper into a one-time buyer. Retailers with slow return processing often see negative reviews post-holiday, even if outbound shipping was flawless. Streamline returns with clear policies and automated return labels. Make it easy for customers and efficient for your team to communicate return deadlines upfront and reduce confusion and inbound inquiries. The right shipping software can help automate return label generation and track return shipments, ensuring a smooth experience for both your customers and your staff [The Cost of Returns: Managing Financial Challenges and Building Customer Loyalty].

🚩 6. Cutting Off Communication

Silence during peak season creates chaos. Customers want updates, carriers need confirmations, and your internal teams need visibility. Lack of communication leads to missed handoffs and frustrated customers who feel left in the dark. A simple proactive email about carrier delays can turn a potential complaint into a trust-building moment. Use proactive notifications for customers and real-time status dashboards for internal teams. Visibility year-round, but especially during peak season, is a necessity [Explore why accurate, fast execution is a prerequisite for credible communication]. When shipping software serves as the source of truth for your shipping operations, it can keep everyone informed and aligned, reducing confusion and building trust.

Why ProShip Is Built for Peak Season

Peak season success depends on speed, flexibility, and resilience. ProShip’s multi-carrier shipping software delivers all three. Our platform is engineered to manage the most demanding shipping environments, simplifying complexity and standardizing workflows so you can execute with precision and control. Decades of enterprise shipping experience mean we’ve seen it all, and our team’s exclusive focus ensures every innovation and support interaction is driven by deep expertise. With ProShip, you gain carrier freedom, strategic flexibility, and growth-driven scalability, empowering your business to adapt and thrive, no matter how complex the challenge.

The Bottom Line

Peak season is unforgiving. The pressure is high, and mistakes are costly, but they are avoidable. By steering clear of these common missteps and leveraging technology to stay agile, you can deliver a peak season performance that strengthens customer trust and drives long-term growth.

When every second matters, ProShip helps you make the right decisions quickly and confidently. That’s how you turn peak season from a stress test into a competitive advantage. Ready to talk with our team? Schedule a discovery call to get started.

Back to Blog

Back to Blog