API, On-Platform, or Hybrid? The High-Stakes Carrier Engine Decision for Enterprise Parcel Shippers

Choosing the Right Carrier Rating Architecture for High-Volume Parcel Shippers

We all love the KISS method: keep it simple, stupid. And over the past few years, parcel shipping tech has been flooded with solutions promising exactly that: simplicity. API-only carrier engines. Orchestration platforms. Automation overlays. AI doing AI things. All claiming to offer faster integrations, lighter IT lifts, and maximum futureproofing.

But in logistics, “simple” only works if it keeps up with the speed and complexity of your operations. And that’s where these shiny promises start to show their cracks.

There’s a persistent myth floating around the industry that carrier APIs alone can solve every parcel logistics challenge. So, what’s the reality? When should you use an API-based carrier engine? When does on-platform make sense? And where does a hybrid approach offer the best of both worlds?

At ProShip, we sat down with our co-founder, Justin Cramer, to unpack it all.

Understanding the Landscape: API, On-Platform, and Hybrid Architectures

Visualize your parcel shipping architecture on a spectrum:

- X-axis: Maintenance burden (low to high)

- Y-axis: Speed and performance (low to high, or seconds per package vs. packages per second)

Carrier APIs sit at the low-maintenance, lower-speed end of the scale (typically). But as shown above, there are occasional exceptions, what we like to call “unicorn” API engines. And when they do exist, we give credit where it’s due.

On-platform engines land on the high-maintenance, high-speed end.

API Engines: Plug-and-Go

✅ Low maintenance

❌ High latency, especially when operational throughput scales up

APIs are appealing and relatively low maintenance. You can “add an account and be done,” avoiding the hassle of updating local rate cards, surcharges, or time-in-transit files.

But for high-volume parcel shippers, API latency, and availability become a real problem in automation-heavy environments (Print-and-Apply (PandA), Autobaggers, Batch/Wave processes, conveyors). More on this later.

Where APIs Work (and Where They Don’t)

In-Store Fulfillment: A Great Fit

Utilizing carrier APIs is perfectly fine here. Most stores only ship a few dozen to a few hundred packages per day, making a bit of latency not operationally harmful. Plus, stores often only use up to three carriers due to space constraints, making APIs an efficient choice.

Warehouses & DCs: The Game Changes

In high-volume distribution centers (DCs), throughput becomes king. For instance, conveyor-based shipping systems process 20-30 packages per minute, non-stop. And conveyors don’t wait. In these environments, API latency becomes a bottleneck.

Even a 500ms call can back up flow, reroute packages to manual processing (the dreaded “jackpot lane”), and cause SLA failures or overtime costs.

Throughput Realities in High-Volume Environments

A typical conveyor-based shipping line allows under 2 seconds total to:

- Scan and send shipment data

- Pull order info from WMS/ERP (30–500ms)

- Rate shop (call to carrier)

- Apply customer-specific business rules

- Select the best carrier/service

- Write back tracking data, costs, etc. to WMS, ERP, etc.

- Generate and return the label

- Return the label to the Printer Applicator

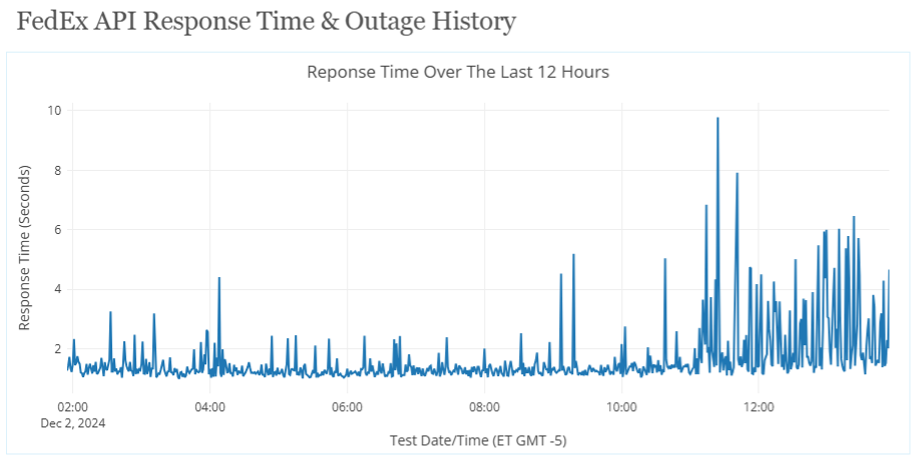

If a single carrier API call takes 550ms or more (check out Carrier API Monitor for live data), it consumes a dangerous chunk of that window. And that’s a best-case scenario...some APIs can spike above 1.2 seconds during peak periods.

Here’s how carrier APIs performed during Cyber Monday 2024:

Warehouses and automated sortation require local rating engines that return decisions in milliseconds, not seconds, to keep operations seamless.

The Other Limits of Carrier APIs (That No One Tells You)

As Justin discussed with us, carrier APIs and carrier API aggregators (platforms or solutions that connect shippers to multiple parcel carriers (like UPS, FedEx, USPS, DHL, etc.) through a single integration point, instead of integrating separately with each carrier's system) have a place, but they come with limitations that shippers need to understand clearly.

❌ No “Ship to Hold” Functionality

You can’t print a label, set it aside, and finalize the weight later. APIs require all shipment details, including (guessed) weight, upfront.

❌ Hazmat? Only If the Vendor Supports It

Carrier APIs technically support hazmat, but only if the software vendor or API aggregator exposes and enables those features. Most API aggregators don’t support Fully Regulated Hazmat or deep Labelmaster integrations.

❌ LTL? Good Luck

Full LTL support, especially options like premise file load, is almost always missing in API aggregators.

❌ High-Volume Batch Shipping

Based off a recent, real conversation we had with a customer: Need batch shipping capabilities for 1,500 shipments done in seconds? This cannot be done via APIs at their current speeds.

❌ No Custom Services

If you’re a very large shipper and a new carrier service is created for you (yes, this happens), most carriers will not want to add that service to their public APIs. Using a solution that can generate on-platform engines means that they can create this service for you, without having to share it with all shippers.

These API limitations aside, feature parity isn’t guaranteed for on-platform engines either. For example, FSMS isn’t capable of multi-piece hazmat shipping, where the FedEx API can accomplish this seamlessly.

Front-of-Line vs. End-of-Line Shipping: The hidden tradeoffs.

Another critical dimension in designing your shipment execution architecture is where rating happens within your workflow.

Front-of-Line (FOL) Shipping: Rating happens before packing at the OMS, wave planning, or pick list level.

✅ Pros:

- Removes rating from the pack/ship process, reducing conveyor station processing time

- Enables early assignment of carrier/service for operational planning

❌ Cons:

- No last-minute optimization

- No dynamic rate shopping or carrier recalibration

- Inflexible to real-time changes (capacity, cost, carrier failures)

- Higher cost leakage risk

FOL shipping locks in carrier selections hours before packages are ready to ship, preventing adjustments when market conditions or carrier capacity change throughout the day. This can result in missed customer commitments and higher cost.

- You lose the ability to choose a better carrier based on final packed weight or dimensions (DIM Weight), which often differ from order-level estimates. Those ROI simulation scenarios? Kiss em’ goodbye.

- If a package is pre-assigned to Ground but misses today’s trailer, it will arrive late unless you pay to expedite. Real-time re-rating at End-of-Line could reassign it to another carrier’s Ground service that still meets the promise at a fraction of the expedited cost.

FOL Use Case: Retailers fulfilling via ship-from-store often ship front-of-line within their OMS. While this works for low-volume store fulfillment, applying it in high-volume DC environments leads to mismatches between rated and actual shipping costs, driving margin erosion over time.

End-of-Line (EOL) Shipping: Rating occurs at the pack station, after items are picked, packed, and dimensioned (aka the true final shipment state). [Dig Deeper]

✅ Pros:

- Accurate final rating and shipment execution. Uses real packed weights and dims, eliminating guesswork.

- Enables real-time rate shopping. Selects the optimal carrier and service level based on up-to-the-second costs, trailer pull times, and SLA cutoffs.

- Minimizes operational exceptions. Reduces rework, mislabels, and jackpot lane slowdowns.

- Maximizes the use of remaining carriers during the trailer pull window to minimize costs for a given customer expectation

- Maximizes customer experience for the lowest logistics cost

❌ Cons:

- Requires fast rating performance (millisecond-level decisions)

- Carrier APIs can’t do it, making on-platform or hybrid essential

EOL Use Case: A warehouse processing 10+ packages per minute at EOL shipping can’t tolerate multi-second API calls. Even a single second of latency per package can create backups cascading down the conveyor, leading to operational delays, overtime, and SLA failures. For instance, an enterprise retail customer of ours utilizes an autoboxing solution that spits out 400 shipments per hour, or just under 7 packages per minute. Using an API carrier can cause something they’ve spent $1M+ on fail. Ouch. On-platform or hybrid is required here.

Front-of-Line/End-of-Line...the Bottom Line

While front-of-line shipping sounds easier on paper, it often masks operational inefficiencies and prevents you from capturing true cost savings and SLA optimization at the point of execution.

End-of-line shipping demands a faster, more reliable rating architecture – typically on-platform or hybrid, but it unlocks maximum operational accuracy, carrier cost optimization, and automation throughput.

Why Hybrid Shipping Architectures Are Winning

This is where smart shippers gain an edge and where ProShip recommends hybrid for most enterprise operations.

A hybrid architecture gives you:

- On-platform speed for automation-heavy warehouses and DCs

- API simplicity for low-volume stores or customer-facing integrations

- Flexibility to access unique carrier features

- Resilience when public APIs fail during peak season

Real-World Example:

Rate shop USPS on-platform for lightning-fast decisions, then print via Endicia’s API to access advanced USPS features. That’s hybrid power.

Bonus: A “premise” engine can still be cloud-hosted

Don’t assume on-platform or on-premise means a server in a closet. Hybrid deployments can span cloud and local resources with smart orchestration.

When Full On-Platform Still Makes Sense

For highly regulated or uptime-critical operations, like pharma or manufacturing, full on-platform remains the gold standard.

- 100% internal control

- Immune to carrier API downtime

- Ultra-reliable performance

Yes, it requires upkeep. But for businesses where every second of downtime costs tens of thousands, the trade-off is worth it.

Justin Cramer’s Recommended Questions to Ask Before You Commit

When evaluating architecture options or vendor solutions, Justin believes that it’s time to dig deep. These questions will help you uncover the real capabilities behind the sales pitch:

✅ How do you support end-of-line shipping within a sub-2-second SLA?

A carrier aggregator may say, "Company ABC ships 300,000 packages a day on our solution, no problem."

What operational workarounds are put in place at Company ABC to achieve this? Is the aggregator using caching and/or multi-threading? These two IT tricks are risky as they may not be allowed by the carriers and could prove to be unsustainable.

It’s also important to ask if that performance is consistent across all shipping nodes. Aka, you’re not just looking for a number. You’re looking for sustained performance under pressure without workarounds.

✅ Are you executing shipping or merely orchestrating it? (Execution = labels generated; Orchestration = carrier suggestions only.)

There’s a big difference. Execution means the system generates labels, completes shipments, and handles exceptions. Orchestration relies on data analytics to find probable savings and customer expectation solutions. You need a shipping execution tool, not an analytics company that also dabbles in shipping execution.

Ask for real examples:

- How do you generate a label when a carrier API fails?

- How do you handle custom shipping labels?

- How will it react when a package size and weight are significantly different than estimated values?

If they can’t show the full shipping cycle, from rate to label to manifest, they’re not executing.

✅ How do you optimize cost based on trailer pool and cutoff windows?

Rate shopping isn’t enough if it doesn’t account for operational constraints. Ask:

- Does the software understand trailer capacity and availability in real time?

- Can it prioritize by cutoff windows dynamically?

- Can it react to midday carrier quota changes?

✅ What’s my team responsible for maintaining, daily and annually?

The devil’s in the upkeep. Clarify:

- Who handles all of the integration work prior to go-live? Are there options?

- Can you handle the integration work if I change a major Enterprise Software Stack piece down the road?

- Who maintains business rules and rating logic if I don’t want to manage it myself?

Hidden operational burdens often show up long after go-live.

✅ Can you deliver a flexible hybrid model, and how does it work in practice?

Again, hybrid shipping architecture blends on-platform reliability with cloud-based flexibility if done right. Discover:

- Can you run labels locally if cloud APIs go down?

- What processes remain functional if APIs get inundated or during outages?

Gauge whether “hybrid” is marketing fluff or genuinely built to flex with your business.

Final Thought: Don’t Trade Simplicity for Speed

Low maintenance is tempting. But low ownership often comes with hidden costs.

APIs can be a great tool. But for high-volume, high-speed operations, they’re not enough on their own. You need speed, accuracy, flexibility, and control all at once.

That’s why hybrid is the quiet hero. Speed without bottlenecks. Features without compromise. Futureproofing without guesswork.

At ProShip, we don’t chase shiny objects. We build systems that match the realities of your operations today and set you up to win tomorrow.

Ready to optimize your shipping architecture for performance and growth?

Talk to ProShip’s experts about building the hybrid model that keeps your supply chain moving.